Road pothole patcher-GXMEP-C4000

Product scope of application:

Road pothole patcher is a fast repairing equipment for asphalt pavement and cement concrete pavement diseases. The main repairing diseases include pits, cracks, cracks, ruts, shoulders and so on. It is widely used in expressways, grade highways, municipal roads and airports.

Product performance advantages:

1. In the uninterrupted construction work, the spraying King discharges 57 kg per minute.

2. Shotcrete King technology has been proved by the long-term follow-up of the "Strategic Highway Research Program of the United States" (SHRP), which is the most effective and cost-effective repair method. More than 97% of the pits repaired by Shotcrete King can maintain their life for more than five years.

3. Operating handle is simple to operate and unique in design. It realizes operator's fatigue-free operation.

4. The whole emulsified asphalt pipeline can be cleaned with less than one liter of cleaning liquid.

5. The nozzle can be cleaned automatically without disassembly and night immersion cleaning.

6. The emulsified asphalt is fed through pressure without asphalt pump.

7. The main system (emulsified asphalt and aggregate feeding system) of Gunbu King has been designed in the same device. The application experience of this system has exceeded 20 years.

8. The King of Painting only needs less than five minutes to maintain every day.

9. The King of Spraying Operators are free from the dirt of blown aggregates and oils.

10. The material will not splash during the construction of the spray repair king. It can be constructed close to the traffic or traffic facilities.

11. Gunning King Gunning System can allow 6.4cm size aggregate to pass through without blocking.

12. Gunbuwang's unique aggregate conveying system enjoys the patent right. The system uses the principles of gravity and aerodynamics to convey aggregate, which greatly reduces the wear and tear of the moving parts (such as screw, blade, hydraulic motor, etc.) in the traditional conveying mode. There are no mechanical moving parts in the conveying system, and the equipment is basically free of maintenance.

13. Unique pneumatic feedback system can effectively prevent aggregate from blocking pipelines.

Product Technical parameters:

Product Model | Pavement Patcher |

Equipment dimensions | (L)8430mm, (W)2450mm, (H)2950mm |

Hopper capacity | 4000L(4m3) |

Weight | 9260kg |

Digital Pressure switch (Xin Yiguan KE-200) |

Range range | -1bar~200MPa |

Service voltage

| 12~35VDC(24VDC Calibration voltage) (24VDC calibration voltage) |

Output relay capacity | 220VAC 3A, 24VDC 5A |

Setting range

|

Set monitoring point for full scale, prevent fluctuation return difference. |

Service temperature | -20℃~85℃ |

Circulation system of heat transfer oil |

Specification of Heat Conducting Oil | 300# |

Fuel tank volume | 6.7L |

Gear oil pump

| Magnetic drive gear pump(MG2015-Y-120/24 Pascal, Nanjing),Direct 24V Magnetic drive pump, DC 24V |

Control method

| Manual

|

Control voltage | 24VDC |

Engine(Cummins 4BTA3.9-C80) |

Rated power | 60kW |

Maximum Torque | 330N·m |

Maximum Torque and Speed | 1500rpm |

idling | 750rpm |

Air blower (Spain PEDRO GIL FRA150/33.2) |

Specifications | 7.80~40.29m3/min,300~1000mbar |

Asphalt tank |

Volume

| 800L |

Net weight of container | 320kg |

Design Pressure | 0.8MPa |

Design temperature | 110℃ |

Maximum working pressure | 0.7MPa |

Proof pressure | 1.04MPa |

Washing tank |

Volume

| left pressure chamber 15L

|

| Right pressure chamber 45L

|

Net weight of container | 90kg |

Design pressure

| Both pressure chamber 0.8M

|

Design temperature | 50℃ |

Maximum working pressure

| Both pressure chamber 0.77MPa

|

Proof pressure | 1.01MPa |

Compressor |

Air displacement

| 183L(2150r/min) |

Working pressure

| 0.8MPa |

Emulsified asphalt |

Specification |

Fast set and fast split, asphalt content is more than 65% |

Aggregate vibrator |

Specifications | 24VDC exciting force:200KG |

Diesel tank |

Specifications | 755mm×350×290 (74L) |

Aggregate |

Aggregate Specification

| clean, diameter from 5mm to 15mm

|

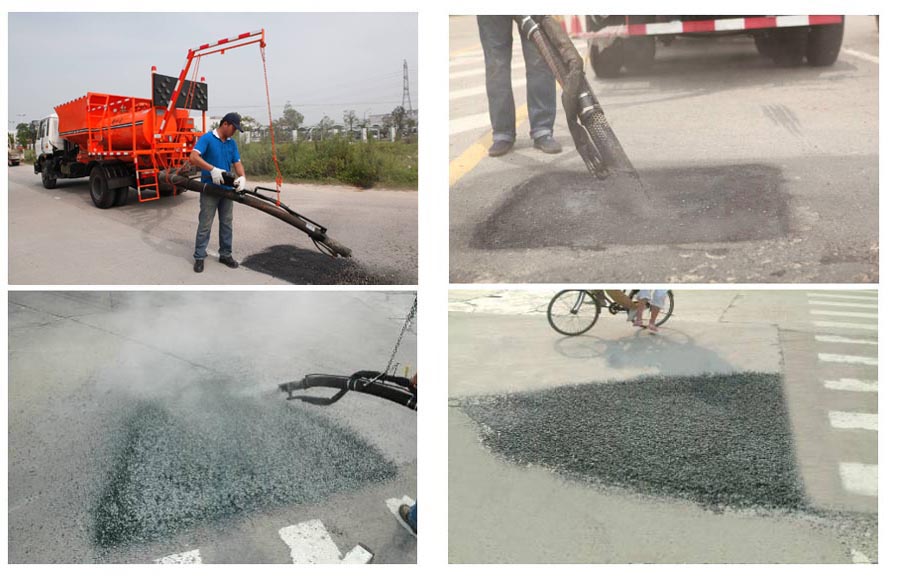

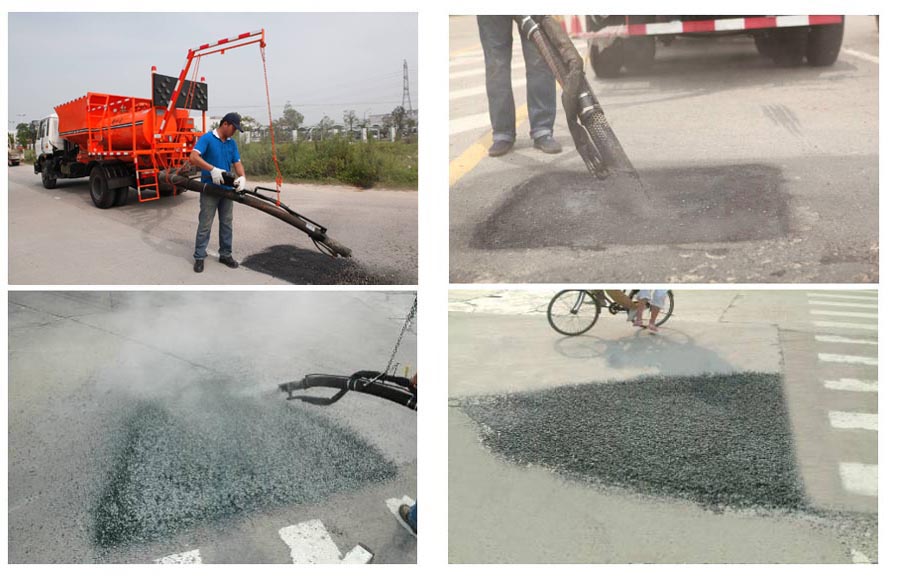

Construction process:

1. Use compressed air to clean the pit and remove any loose materials and water in the pit.

2. Spray a layer of emulsified asphalt on the inner surface of the pit.

3. Spray the mixture of emulsified asphalt and aggregate into the pit.

4. Put a layer of dry aggregate on the top of the pit to make it have a surface sealing layer, thus completing the sealing work.

5. Traffic can be opened immediately after repairing, and there is no need to use flat-plate rammer or compactor for compaction and flattening (flat-plate rammer or roller is commonly used for compaction in domestic construction).

You choose not only reliable products,There are also high-quality services!